Acadlore takes over the publication of IJCMEM from 2025 Vol. 13, No. 3. The preceding volumes were published under a CC BY 4.0 license by the previous owner, and displayed here as agreed between Acadlore and the previous owner. ✯ : This issue/volume is not published by Acadlore.

Numerical Modeling and Analysis of Viscous Media Removal from Grooved Surfaces with Rotating Impinging Jets

Abstract:

Surface cleaning prior to coating and fabrication processes is an important process to ensure the quality and proper functioning of the products. The current work involves the modeling of a cleaning process where viscous media is removed from surfaces using mechanical force from impinging water jets. The jets are mounted on a rotating nozzle carrier, which combine the normal force with increased tangential force resulting in the removal of oil present in the grooves of metal surfaces.

The modeling of such a process is performed with the volume of fluid (VOF) method with an open source Computational Fluid Dynamics (CFD) code Open-FOAM®. Rectangular grooves, which represent an idealized form of roughness are considered for numerical analysis. The oil present in the roughness grooves is resolved by the computational mesh.

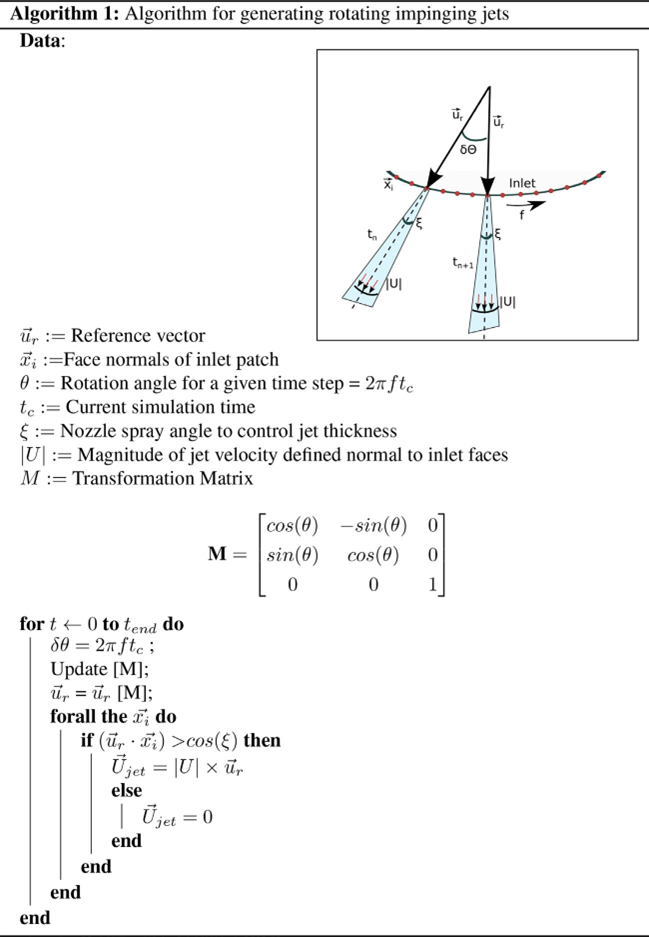

The inlet is modified to model the phenomenon of rotating jets. In order to model the effect of rotating jets, a reference vector is transformed by a time-dependent rotational tensor. All the faces which make a certain angle (opening angle) with the reference vector are activated. This results in the formation of jets with a thickness which can be controlled by the opening angle. The numerical model is used to study the influence of the frequency of rotation, nozzle exit velocity, viscosity of oil and the aspect ratio of the grooves on surface cleaning. An impinging turbulent jet is modeled using the k-epsilon turbulence model.

Finally, the CFD simulations are qualitatively compared with a previously developed semi-empirical model and experiments conducted in an industrial setup. The tendencies of oil removal due to the effect of the process parameters observed in the simulation are in close agreement with the semi-empirical model and experimental results. Thus, the cleaning model can be used to conduct sensitivity analysis to achieve an optimal performance of the cleaning process.